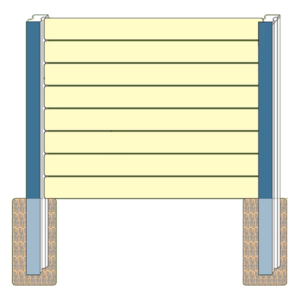

Specification of Vertical concrete posts as well as horizontal planks were cast using prestress technology with a designed concrete mix to achieve maximum durability and strength. We manufacture our product in the company and install it on at the side.

It is vibrated by a vibrating machine. Planks and beams are put in chlorinated water for the required amount of time (Minimum 15 days)